Overview

Dams are significant pieces of infrastructure that provide safe drinking water, irrigation, flood mitigation, and energy, and support the extraction of minerals. In Queensland, there are 107 referable dams, and an estimated 790,000 people live downstream who would be at risk if these dams were to fail. Queensland state entities and local governments own 92 of these dams.

Tabled 8 December 2021.

Report on a page

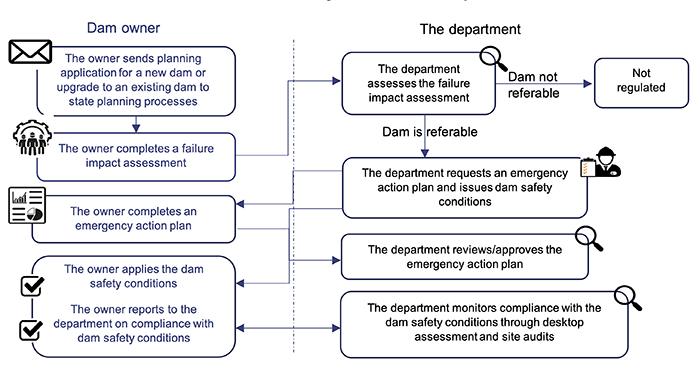

This audit examined how the Department of Regional Development, Manufacturing and Water (the department) collects and uses information from owners to manage risks to dam safety. Figure A shows how we expected the department to use information to manage risks.

Queensland Audit Office.

We concluded that the department is not effectively managing the information it collects or targeting risks to non-compliance. We recommend the department collects and stores information on the level of non-compliance accurately and then acts on non-compliance, using the full range of enforcement measures at the department’s disposal to address serious or persistent non-compliance.

Collecting information |

The department has approved processes for collecting the information for the legislated safety requirements. However, it is not effectively collecting information on its dam safety upgrade schedule. The schedule (set in 2005) gave owners targets to upgrade dam spillways based on their capacity to safely release floodwaters. The department is not effectively monitoring progress to ensure all the upgrades will be completed by the upcoming 2025 and/or 2035 deadlines. Eight spillways must be upgraded by 2025 and 30 by 2035, with total costs estimated at $3.1 billion.

The department’s dam monitoring system does not effectively monitor compliance with all its safety requirements. It uses spreadsheets to monitor compliance but the individual spreadsheets are not up to date, complete or accurate. This makes it difficult for the department to track whether dam owners are conducting and providing key reports on dam safety inspections on time. We found examples of inspection reports being significantly overdue (see Appendix C).

Managing risks |

The department has developed a risk prioritisation process, based on the eight risk factors recommended by the 2012 Queensland Floods Commission of Inquiry, to inform half its dam site visits. It also considers additional factors for the other half, that are not risk-based or well-documented, such as availability of resources, workload and budget constraints relating to travel.

Acting on non-compliance |

The department has worked on developing good relationships with dam owners as part of its strategy to promote voluntary compliance. It runs workshops and training for owners and the community to increase understanding of dam safety principles and compliance requirements. The department relies almost exclusively on encouraging voluntary compliance to dam safety conditions and is reluctant to use the full range of enforcement options available. It is not ensuring all owners comply quickly enough with all the legislated reporting requirements when it identifies non-compliance with dam safety conditions.

1. Audit conclusions

The Department of Regional Development, Manufacturing and Water (the department) has the key design elements of an effective regulatory framework. However, it is not effectively or consistently applying some important elements of the framework. There are gaps in the way it collects and manages the information it needs, how it targets risks, and how it acts on non-compliance. The department needs to improve its regulatory approach to compliance, monitor dam owner planning and progress in achieving necessary upgrades, and better address non-compliance by owners.

The department does not effectively collect the information it needs to conduct targeted, risk-based inspections, making it harder to enforce compliance with dam safety conditions. Weaknesses in the system and processes for monitoring and recording information on dam safety conditions reduce the department’s ability to inspect and enforce the conditions.

The department does not identify non-compliance with dam safety conditions consistently. When it does identify non-compliance with dam safety conditions, the department does not always follow up with owners to ensure issues are adequately addressed. Consequently, the department does not have complete and up-to-date data on the level of non-compliance and risk across its regulated population (dam owners).

The department has developed good relationships with dam owners to promote voluntary compliance. It runs workshops and training for owners and the community to increase understanding of dam safety principles and compliance requirements. It has recently focused on improving compliance for emergency action plans, with no outstanding plans identified from its review of the 2020 plans. While these are positive and important elements of regulatory practices, the department needs to improve its processes to enforce compliance.

The department focuses on voluntary compliance but has been reluctant to use enforcement measures such as penalty infringement notices or court action when needed. It has not made use of the available enforcement actions even though there are examples of owners consistently not providing the legislatively required safety notifications and reports on time. It cannot assess whether the dams are compliant with the safety standards if the safety reports are considerably late or not provided at all.

These gaps in information gathering, systems, monitoring and enforcement practices limit the department’s effectiveness as a regulator.

2. Recommendations

|

Overall recommendation for the Department of Regional Development, Manufacturing and Water |

|

|

Specific recommendations for the Department of Regional Development, Manufacturing and Water |

|

We recommend that the Department of Regional Development, Manufacturing and Water:

|

Reference to comments

In accordance with s. 64 of the Auditor-General Act 2009, we provided a copy of this report to the Department of Regional Development, Manufacturing and Water. In reaching our conclusions, we considered its views and represented them to the extent we deemed relevant and warranted. Any formal responses from the entity are at Appendix A.

3. Collecting dam safety information from owners

This chapter provides our key findings on how the Department of Regional Development, Manufacturing and Water (the department) collects the legislated dam safety information from owners of referable dams. The state’s 107 referable dams are owned by state entities (Sunwater, Seqwater, Stanwell Corporation, Department of Resources, and CleanCo), local governments, private owners and industry (mining and pastoral companies).

A dam is referable if a failure impact assessment demonstrates there would be two or more people at risk if the dam was to fail.

Dams are subject to regular mandatory inspections by registered engineers to give owners and the department assurance that they comply with safety standards. Owners must provide a range of safety information to the department, including copies of failure impact assessments, emergency action plans and safety inspection reports on compliance with dam safety conditions.

The department conducts desktop assessments of the reports and notifications to ensure that owners are complying with the requirements of the Water Supply (Safety and Reliability) Act 2008 (the Act). Figure 3A shows the information the legislation requires owners to provide to the department to show compliance with dam safety conditions.

Queensland Audit Office from the Water Supply (Safety and Reliability) Act 2008.

Does the department collect the information it needs? |

The department does not collect sufficient and consistent information from all owners to know if they can meet all the requirements of the Act. It collects information for most of its safety requirements but does not collect sufficient information from owners on the status of plans and progress to ensure compliance with its dam safety conditions on acceptable flood capacity.

The department has developed processes for collecting and monitoring some of the information owners must regularly provide under the Act. Figure 3B shows its processes for collecting and monitoring compliance with the Act’s information requirements.

|

Dam safety component under the Act |

Department guideline |

Department business processes |

|---|---|---|

|

Failure impact assessments include the information needed to decide whether a dam is referable. |

Guideline for failure impact assessment of water dams, 2018 |

Documented workflow for staff to follow for requesting and assessing failure impact assessments. |

|

Emergency action plans document how to minimise the risk of harm to people or property if a dam hazard event or emergency happens. |

Emergency action plan guideline, 2020 |

Documented workflow for staff to request and assess emergency action plans |

|

Dam safety conditions are applied by the department to each referable dam. Owners are required to complete inspections and report on compliance with the conditions. |

Dam safety management guidelines, 2020 |

Documented workflow for staff to collect and assess dam safety conditions and audit compliance (10 dams annually) with the safety conditions. |

|

Emergency event reports must be prepared within 30 business days of the end of the emergency incident. |

Emergency action plan guideline, 2020 |

A documented workflow was drafted but not finalised. |

Queensland Audit Office based on Department of Regional Development, Manufacturing and Water guidelines and processes.

The requirements under the Act for owners to provide information to the department are covered by various guidelines made available on the department’s website. The department has a range of options to enforce dam safety standards and conditions under the Act.

The department has approved processes for collecting the information for all its safety requirements. Since 2017, it has invested in developing a consistent regulatory process and in 2020 achieved external accreditation for its adopted quality system. There is, however, a gap in how it monitors some of its information collection. It has not developed clear guidance for staff on how to consistently monitor compliance with dam safety conditions. The department plans to complete 10 audits per year, so monitoring of compliance with the dam safety conditions may take more than 10 years to cover all 107 dams.

One of the key dam safety conditions is for dams to comply with the department’s acceptable flood capacity guidelines. In 2007, the department issued its first Acceptable Flood Capacity Guidelines (previously part of the Queensland dam safety management guideline, 2002). It gave dam owners time frames to comply with the guidelines depending on the assessed discharge capacity of the spillways and/or the dam’s capacity to store floodwaters. Owners need considerable lead time to plan, design and construct upgrades to spillways. Owners with five dams or more (Seqwater and Sunwater) need to provide more details on their dams than other owners. This includes more detailed information on how and when they will complete dam safety upgrades.

A spillway is a weir, channel, conduit, tunnel, gate or other structure designed to permit discharges from the reservoir when storage levels rise above the full supply level. Spillways ensure the water flows safely away and does not damage the dam wall or other structures.

Sunwater and Seqwater are the only owners in Queensland with more than five dams, with 22 and 25 dams respectively. They need to upgrade 20 of their dams by 2035. The department received information on dam upgrades from Seqwater (in 2013) and Sunwater (in 2017). It continues to receive updates on their schedules, which can change if and when emerging risks are discovered or when risks previously escalated are reprioritised. The department is represented on working groups for some of these upgrades. The risk assessments allow the department to monitor the progress of Sunwater and Seqwater’s upgrade program.

For dams not owned by Seqwater and Sunwater, the department is not consistently requesting upgrade progress reports. The department has not issued similar dam safety conditions for the other owners to give sufficient notice of upgrades. It engages directly with each specific owner that it considers may not be able to meet its scheduled time frames (2025 and 2035). There is no clear basis for how these decisions to extend the time frames were made. Some dams have safety conditions requiring owners to provide 12 months’ advance notice of dam upgrades; others have no requirement.

Without early notification of time frames, the department has limited ability to monitor progress against a dam upgrade. It also reduces the time it has to assess the various stages of design, tender, construction, hand-over and operation, and to intervene if necessary. The next section provides more details on the spillway upgrades schedule.

Are spillway upgrades being monitored? |

Scientific advancements since many dams were designed and constructed mean engineers now have a better understanding of rainfall, hydrology (where the water flows), and the impact of climate change on the frequency and severity of weather events.

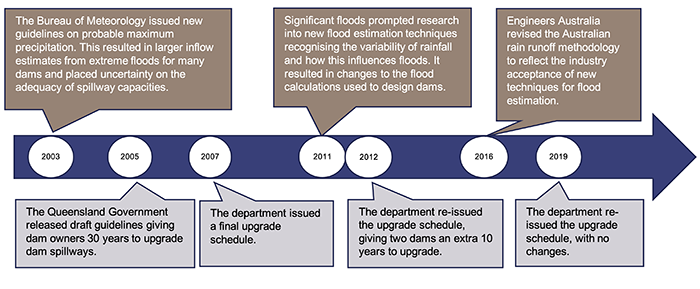

As shown in Figure 3C, the Bureau of Meteorology issued new guidelines on probable maximum precipitation in 2003, particularly in the tropics and sub-tropics.

Queensland Audit Office analysis of Department of Regional Development, Manufacturing and Water reviews and guidelines.

The change in how serious flood events can affect a dam (see boxes in brown in Figure 3C) have had a significant impact on calculations to determine the capacity of dams’ spillways in Queensland.

The department issued guidelines and gave owners of dams with inadequate spillway capacity 30 years to complete all upgrades (2035) and comply with the flood capacity safety standards. The schedule it provided requires owners to upgrade their spillways based on their capacity to safely release floodwaters from extreme flood events. The schedule set out the following time frames for owners to upgrade their dam spillways:

- as soon as possible (from 2005) for spillways with 25 per cent capacity

- 2015 for spillways with 50 per cent capacity

- 2025 for spillways with 75 per cent capacity

- 2035 for all spillways to be at 100 per cent capacity.

In comparison, in 2010 the New South Wales Dam Safety Committee updated its acceptable flood capacity guidelines. It gave owners two, 10 or 20 years to progressively address spillway capacities. It also required owners to submit a revised assessment of their spillway capacities for it to approve the assessment methodology and upgrade proposals.

The department was unable to provide an analysis of the risks associated with setting the 30-year time frame. We noted New South Wales adopted different time frames. Without an analysis of the risks for these time frames, it is not possible to determine if Queensland’s time frames will ensure safety risks are managed effectively.

All the dams in Queensland scheduled for upgrade by 2015 were either completed or rescheduled by the department to 2025. The department does not have a formal requirement for owners to provide information on the progress of the upgrades by 2025 and 2035. Without these commitments, the department has no way to monitor owners’ progress in achieving the upgrades by the due dates.

The department did not require owners to commit to time frames to start the planning, design and build phases to meet the upgrade schedule dates. Seqwater (in 2013) and Sunwater (in 2017), who collectively own around half of the dams requiring upgrades, voluntarily provided the department with information on their planned upgrades.

The department monitors progress of spillway upgrades based on the number of dams owned.

There are 38 dams scheduled for upgrades by either 2025 or 2035. Of these, eight are required to provide information to the department 12 months in advance on when and how they will upgrade their dams. The owners of 13 dams needing upgrades have no dam safety conditions requiring them to give the department advance notice of how and when they will meet the dam upgrade schedule. This gives the department limited time to intervene if there are delays or the proposed upgrades are not going to meet the safety standards.

Owners have known since 2005 that they need to upgrade inadequate spillways to meet the standards. Some owners have completed upgrades to meet the schedule in the acceptable flood capacity guidelines. Figure 3D lists the progress of the upgrade schedule.

|

Status |

Number |

Costs |

|---|---|---|

|

Upgrades have been completed |

22 |

$0.96 bil |

|

Upgrades needed by 2025 or 2035 |

27 |

$1.17 bil |

|

Some upgrades since 2006 but require further upgrades |

11 |

$0.25 bil 1 $2.23 bil 2 |

|

Not been upgraded or identified as needing an upgrade |

47 |

nil |

|

Total |

|

$4.61 bil |

Note: 1 This is the value of upgrades completed. 2 This is the value of further upgrades still to be completed.

Department of Regional Development, Manufacturing and Water.

|

Recommendation 2 We recommend the department revises the acceptable flood capacity guidelines, requiring dam owners to advise it how and when spillways scheduled for upgrade will be completed and report progress. |

Are assessments of spillway capacities up to date? |

Four private owners on rural properties (with a combined total of 48 people at risk), have not assessed the acceptable flood capacity of their dams since the department:

- issued its acceptable flood capacity guidelines

- designated them as referable.

Consequently, neither the department nor the owners are aware of whether their spillways would be able to meet the current acceptable flood capacity guidelines. The department is not proactively using its legislated ability to gather information to ensure owners have up-to-date assessments and that owners and the department fully understand and manage the safety risks.

The department used (from the year of the last known assessment) the capacity of the spillway to inform the upgrade schedule and identify those spillways to be upgraded. Engineers calculate the spillway capacity at the time of construction or as part of major works, typically as part of a risk assessment (which also considers risks such as earthquake, gate failure, previously unforeseen structural concerns, and so on). It is reviewed every 20 years as part of the safety review unless the more frequently conducted engineering inspections suggest otherwise.

The calculations of spillway capacity of some of the state’s referable dams have not considered the impact of the changes to the probable maximum precipitation guidelines, new hydrology models, and the revised rainfall runoff methodology. This has a greater impact on the higher consequence dams that are required to pass rarer, more extreme flood events. For lower consequence dams there may be little to no impact.

There are seven dam consequence categories from Very Low to Extreme. The ratings are based on the consequences of a potential dam failure and the severity of risk to human life and damage and loss.

The department’s acceptable flood capacity guidelines give it the ability to request a written acceptable flood capacity assessment be prepared by an independent registered professional engineer for the current dam arrangement. Industry good practice suggests that owners should reassess acceptable flood capacity at least once every 20 years. Conducting this assessment more frequently could help owners and the regulator better understand the risks to their dams.

|

Recommendation 3 We recommend the department reviews frequencies for conducting risk assessments and/or flood capacity for dams, particularly those conducted more than a decade ago that may have underestimated flood risk. |

Who is tracking due dates of reports and notifications? |

Due to deficiencies in the current referable dams register, engineering staff spend considerable time attending to non-technical tasks, for example, tracking of due and overdue notifications and reports.

The department uses a site audit register spreadsheet to track the recommendations its principal engineers make after site audits. But the register was not completely up-to-date. Five of the 20 dam safety site audits done in 2020 were not recorded in the dam site audit register and were not being followed up on.

|

Recommendation 4 We recommend the department maximises the engineering expertise available by adopting appropriate work processes, systems, and team structure to enable consistency across all areas of compliance. |

4. Identifying and managing risks

This chapter provides our findings on how the department identifies and manages risk. We assessed how the department prioritises its compliance program to ensure dam safety documentation complies with the standards. We also assessed its approach to targeting enforcement and compliance based on the assessed risk.

Does the department identify risks effectively? |

The department’s 10-year audit cycle is based on its available resources for carrying out audits. Further work is needed by the department to assess if its 10 audits a year is sufficient to reduce both the level of harm that would arise from and the probability of non-compliance with the specific dam safety elements audited.

The department’s schedule for auditing dams for safety risks (its prioritisation schedule) needs more accurate information on dams with the highest safety risk. This is needed to inform the department’s decisions about which dams to audit first. Incorrect data has led to some dams that are a higher safety risk not being prioritised or being left out of the audit schedule for the next three years altogether.

There are 107 regulated dams in Queensland. The department needs to ensure it has adequate resources to inspect the dams and target those with the greatest safety risks. The primary means of identifying safety concerns at a dam are periodic engineering inspections and safety reviews by competent technical specialists, the frequencies of which are guided by industry standards.

The department’s site audit program, strategy, and plan clearly detail how it prioritises the 10 dams to audit in each of the next three years. The department has not documented why 10 audits per year is appropriate to reduce the risk of non-compliance with dam safety requirements. The 2020–21 plan identifies that the target of 30 dam site audits to be conducted over the coming three years reflects the present availability of resources and its workload.

The department’s site audits are conducted to:

- assess compliance with regulatory requirements—including dam safety conditions

- assess the general condition and safety of the dam.

The Australian Productivity Commission, Regulator Audit Framework 2014 suggests that regulators determine the level and frequency of auditing by considering the following:

- both the level of harm that would arise from and the probability of non-compliance causing harm with the specific safety elements audited

- the likelihood that compliance with the specific safety elements audited will actually reduce the probability of events and/or the harm associated with an event.

The department’s endorsed dam safety site audit strategy and plan includes a clear prioritisation process to identify those dams with the highest safety risk. It includes eight risk factors recommended by the Queensland Floods Commission of Inquiry. They are the:

- structure and materials used in construction

- age of the dam

- time since last inspection

- occurrence of a flood event since the last audit and the size of that flood event

- population at risk if the dam were to fail

- experience and capability of the dam owner

- dam owner compliance history

- time since last audit (there were errors in these dates).

The first step in the prioritisation process is to consider the above factors and rank the 30 dams with the highest safety risks for audit in the coming three years in a spreadsheet. Poor internal controls over the data used to prioritise the visits led to errors in the calculations.

Internal controls are the people, systems, and processes that ensure an entity can achieve its objectives and comply with its frameworks, policies and applicable laws.

The dates the department conducted the last audits were incorrect in the prioritisation spreadsheet. After recalculating the ranking using the correct last audit date, 97 percent of dams had their prioritisation ranking change. Only 10 of the dams that were in the top 30 in the Dam Safety Site Audit Strategy and Plan 2020/21–2022/23 remained in the top 30. Figure 4A shows the error would have resulted in the department not achieving its target of 15 audits of the dams with the highest dam safety risk from the eight risk factors.

|

Audit year |

Number of dams in the forward audit plan ranked in top 30 based on QAO recalculation |

Number of dams in the forward audit plan not ranked in top 30 highest risk dams |

|---|---|---|

|

2020–21 |

4 |

6 |

|

2021–22 |

4 |

6 |

|

2022–23 |

2 |

8 |

|

Total |

10 |

20 |

Queensland Audit Office based on the Department of Regional Development, Manufacturing and Water records.

The department’s next step is the consideration of additional factors (including new or emerging issues, availability of resources, staff workload, and budget constraints relating to travel). How these additional considerations are applied is not documented. Half the annual visits are determined by these additional considerations. The department has not assessed if the constraints on its prioritisation process are achieving the right balance between the risks to public safety and how it manages its resources.

Finally, the department’s engineers review the priority order, as a quality check based on their own knowledge of the dams.

|

Recommendation 5 We recommend the department revises and documents its process for selecting the number and priority of dam site audits to ensure it is reflecting industry good practice. This should balance the value of on-site inspections and face-to-face dialog with dam operators with the time needed to cycle through the audit population. |

Is the risk of capacity to pay for the dam upgrades managed? |

The department’s risk prioritisation process includes critical factors that can help it assess non-compliance with the dam safety requirements. It does not include capacity to pay for dam upgrades as a risk factor, which reduces its ability to target owners who may be slow to complete upgrades due to financial pressures.

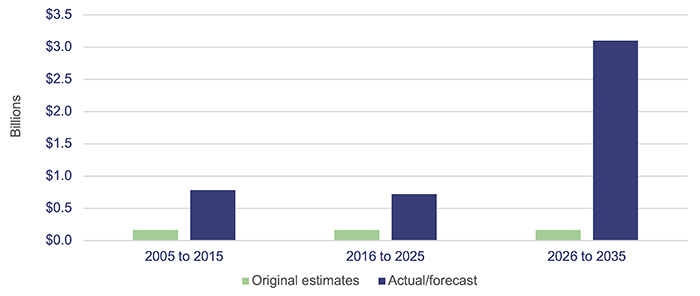

Capacity to pay can be an important issue in assessing the risk of maintenance or upgrade programs. There is a risk that owners might not address safety issues and not comply with legislated standards or industry good practice if they do not have the capacity to pay for upgrade works and operating costs of the asset. This is a risk the department needs to consider as part of its risk assessments. Figure 4B shows how much owners have advised the department they have already spent on upgrades to meet the acceptable capacity standards and how much they still need to spend.

Note: The forecast costs from 2026 to 2035 are not finalised and project costs for large dam upgrades are subject to significant uncertainty.

Queensland Audit Office from Department of Regional Development, Manufacturing and Water data and estimates. We have not audited these estimates.

The department estimated the upgrade costs to be around $500 million. These early cost estimates were not based on full engineering investigations, which can take many years to develop per dam, and may not have considered costs associated with the inclusion of additional benefits such as increased water supply and flood mitigation. The final costs will depend on further engineering reports, consideration of different construction options to achieve the standard, and business case outcomes for enhancements.

The original 2005 upgrade schedule planned to evenly distribute the costs over the 30 years. Current estimates to achieve the 2035 target are approximately $4.6 billion, much higher than originally proposed. The greatest costs are for the portion of dams scheduled for 2035. The department does not have a fully costed timetable for when owners will complete the 2025 and 2035 upgrades. It has not actively managed the risk that affordability of significant upgrades could delay safety upgrades.

Considering capacity to pay for upgrades as a factor in determining its compliance program may give the department an ability to better target its compliance efforts on owners not on track to meet the upgrade schedule. This may help the department manage the risk of non-compliance due to unaffordability.

|

Recommendation 6 We recommend the department revises its risk factors to include consideration of a dam owner’s capacity to pay, based on forward budgets and plans, when prioritising compliance activities for dam upgrades. |

Does the department monitor non-compliance well? |

The department’s Referable Dams Register (which is its dam monitoring system) is used effectively to monitor compliance with emergency action plans. It does not, however, meet the department’s requirements for monitoring compliance with dam safety conditions. This reduces the department’s ability to develop an integrated assessment of each dam and owner to inform its compliance program.

The department’s dam safety team stores compliance information in multiple spreadsheets that are not maintained consistently or regularly. There is a risk that dam deficiencies and safety issues are not identified and recorded by the department and not followed up to ensure compliance with the legislated safety requirements.

In 2011, the department (then the Department of Environment and Resource Management) identified the need for an information system that would improve reporting and compliance. It planned to use the system to record information on all its compliance activities. It also needed the information to inform the risk factors (recommended by the Queensland Floods Commission of Inquiry) it uses to prioritise dam safety site audits.

The original business case estimated the project’s costs to be $1.726 million, noting an initial preference to roll out the project across two regulatory entities. The former Department of Natural Resources, Mines and Energy reported a final project cost of $1.245 million to the Queensland Government’s digital projects dashboard in December 2018. The vendor completed an enhancement project in September 2020.

Initially the system was slow and unreliable. The 2020 enhancements allowed the dam safety team to more effectively use the system to manage three of its four key compliance activities: failure impact assessments, the emergency action plans, and the annual 1 October safety notifications of compliance with the dam safety conditions. The department has not yet enhanced the system to be able to manage its dam safety condition information. Individual staff are recording information on dam safety conditions in separate spreadsheets exported from the system. These spreadsheets are stored on a SharePoint system that provides version history and tracking of edits, however no one monitors the changes or edits made.

The separate spreadsheets store:

- dam safety conditions—Each engineer maintains a separate spreadsheet for their own portfolio of dams. The spreadsheets are inconsistent and, in one case, not up to date. This reduces the team’s ability to ensure a consistent approach to compliance

- emergency contact information—A single spreadsheet has key safety information about all referable dams, including the emergency contact details of owners and local emergency management groups. The dates for when the dams were last audited is inaccurate

- dam site audit visits—Each of the three teams has a single sheet within the dam site audit findings register spreadsheet on which it records the details of audits (including recommendations to address safety issues and deficiencies). These spreadsheets are not up to date and, in some cases, audit completion dates are inaccurate.

The department has not maintained strong controls over the information in these spreadsheets. It is not managing:

- version control over the information (beyond that provided by SharePoint file storage functionality)

- access/edit permissions (beyond that provided by SharePoint security protocols, the spreadsheets are not locked down—everyone in the dam safety team has access)

- monitoring and keeping an audit trail of changes.

The dam monitoring system is not able to reliably produce a report with up-to-date information on the dams and their owners. This has contributed to the data accuracy issues reported in the next section.

The 2020 enhancements to its register have allowed information on emergency management and response compliance to be stored and managed within the system. There were no outstanding emergency action plans from the 2020 round.

Tracking safety issues identified in safety inspections

The department receives and reviews externally prepared safety inspections but it is not consistently recording issues raised, or consistently monitoring how owners are addressing them. There is a risk that if owners do not address safety deficiencies within the time frames recommended by the engineering report, they could get worse.

The dam safety conditions require owners to submit copies of externally commissioned inspection reports at set frequencies. The department does not maintain a register of significant issues identified in all the reviews and reports by professional engineers. It was monitoring issues identified in some reports, but it has not developed consistent guidance for its engineers about how to determine which issues are significant enough for them to track and follow up with owners.

A set of consistent guidelines outlining how to record issues and a register to monitor them will allow significant safety issues raised in the safety reports to be consistently managed and tracked.

|

Recommendation 7 We recommend the department better aligns the Referable Dams Register (which is its dam monitoring system) with the compliance outcomes needed, to ensure a more centralised and consistent way to accurately capture owners’ compliance information. |

Targeting non-compliance

Due to some cases of data inaccuracy in the Referable Dams Register, the department is unable to manage, report and store information in a way that easily allows it to identify owner compliance. This reduces the department’s ability to identify when notifications and reports are due and overdue. As a result, some owners are not completing and submitting their dam safety reports and inspections on time. This hinders the regulator’s ability to identify safety risks and take appropriate action. Refer to Appendix C for a list of examples of overdue or not received reports.

The regulator’s ability to understand the risk of non-compliance with the dam safety standards relies on the assessments of the safety issues raised in notifications and reports it requires owners to provide. It cannot assess the risk of non-compliance if the owners do not provide the reports on time.

We assessed a random sample of due dates and received dates for reports, and identified that the department’s dates are inaccurate. There are different types of errors, including:

- incorrect due dates

- received dates being for the wrong reports

- received dates being the date the inspection was prepared by the consultant rather than the date it was received by the regulator.

Due to the errors in the data, the percentage of owners providing the required reports and notifications on time is unclear. However, Appendix C provides some examples we manually verified of the types of reports that were late. Some of the legislatively required reports were significantly late, in one case by five years. One owner we visited commented on the lack of follow up by the department on late reports.

As at 10 February 2021, eight significant safety reports and 14 annual notifications were overdue as they were due but had not been received. Figure 4C shows the number of the various notifications and reports still outstanding that owners are legislatively required to provide. The emergency action plans from 2020 were all provided within the time frames required or owners provided the department with reasons for any minor delays.

|

Notification or report |

Number outstanding as at 10 February 2021 |

Average number of days the reports have been overdue |

|---|---|---|

|

Annual dam safety conditions notification |

14 |

132 |

|

Annual safety inspection |

2 |

117 |

|

Five-yearly comprehensive safety inspections |

3 |

945 |

|

20-year safety reviews |

3 |

2,112 |

Note: The outstanding reports include those that were due but had not been received on the date extracted.

Queensland Audit Office from Department of Regional Development, Manufacturing and Water data.

|

Recommendation 8 We recommend the department improves its records management processes and practices, including accurately documenting when inspections and reports are due and received. |

Does the department act on non-compliance? |

The department is not effectively managing non-compliance issues with owners adequately or in a timely way. Often it does not follow up on overdue and late reports, or is slow to do so. It does not provide clear guidance to staff on when to escalate non-compliance and does not maintain a register of compliance actions (compliance notices or penalty infringement notices). The department has the authority to issue compliance notices, but this is not done consistently or in a timely way.

The department relies on encouraging voluntary compliance to dam safety conditions through an informal escalation process of engagement and discussion with owners, training and education, reminder letters and warnings. The department has not ensured that owners provide the legislatively required notifications and reports on time or, in some cases, at all.

The department can issue penalty infringement notices (fines) to owners who fail to comply and in extreme cases can prosecute owners. However, the department was unable to provide evidence of any infringements being issued or prosecutions commenced since 2012, despite instances of some owners consistently not complying. It expressed reluctance to consider penalty infringement notices and prosecution as enforcement actions on the basis that it considers voluntary compliance activities generally sufficient in achieving safety outcomes.

As the department takes a risk-based approach to compliance, it is critical that it receives the safety reports and notifications from owners on time, so it can assess any safety issues raised. The department cannot respond to safety risks in a timely way if the reports and notifications are delayed or not provided at all.

The Water Supply (Safety and Reliability) Act 2008 gives the department authority to enforce dam safety standards and conditions. The department has a compliance strategy that is based on five strategies: guide, inform, enable, monitor, and enforce. The strategy includes a range of statutory and non-statutory escalation actions. Non-statutory actions include:

- no action (engagement and dialog if there is a reasonable excuse or statutory time limits expire)

- training and education

- reminder letters/emails

- warning letters.

Statutory actions include:

- information request

- notices (refusal, show cause and compliance)

- investigation

- prosecution.

The department’s escalation actions do not detail the thresholds for when it will use the different statutory and non-statutory actions. It is currently left to the discretion of each team to determine which type of action to apply when an owner does not provide the legislatively required report or notification. For example, it is not clear how many days/months late a dam safety review needs to be to trigger a warning letter, and then a refusal or show cause notice to be issued. In one case, a dam safety review was two years overdue before the department sent a reminder email. The owner eventually provided the report three years later (five years late).

The department’s compliance data is inaccurate, so overall non-compliance cannot be determined reliably.

Our analysis of the department’s actions to achieve compliance is detailed in Appendix C. It shows that, for 11 cases selected, reports were overdue by between 48 days and four years and that the department was either slow to act or failed to act.

The department’s approach to receiving the notifications and reports on time is to promote voluntary compliance by working with industry to encourage compliance and best practice. Its activities to achieve compliance and reduce risks are:

- leading the industry by continuously reviewing standards and guidelines, consulting and engaging with industry, providing training and education, and support of and contribution to research and development

- undertaking dam site audits to ensure that owners are compliant with standards, providing ongoing training and education for owners and stakeholders

- implementing an internal quality system to ensure the dam safety unit has transparent, consistent application of process.

The department is not diligently following up owners to collect overdue reports. The full extent of non-compliance cannot be analysed as the department’s data is unreliable and it does not maintain a register of enforcement actions, such as issuing warning letters. There are, however, multiple examples of safety reports that are years overdue. As an example, we found 22 comprehensive inspection reports since 2015 that were late and the department could not provide a reason.

The department’s use of non-statutory actions is not currently acting as a deterrent and ensuring owners provide the legislatively required dam safety information on time, and the department is not taking more substantial enforcement actions.

|

Recommendation 9 We recommend the department sets clear escalation thresholds and acts in a timely and effective manner to address identified non-compliance and record outcomes of enforcement. |

Understanding your dams

This Queensland Audit Office interactive map allows you to explore information on Queensland dams, including dam ownership, location, planned upgrades and the structure, capacity and age of dams.